An important check missed by many builders is proper synchro operation. A synchronizer is pretty ingenious in its design and requires perfect timing and application of force in just the right spot in order to operate efficiently. When people blindly install new synchros, they are not always in perfect alignment and this can seriously affect life and performance.

At Jacks Transmissions, we spend an enormous amount of time making absolutely sure your synchro is set up correctly. Most people will polish them, maybe add more oil channels, but you never hear of anyone changing the preload timing and tooth contact area to allow for superior operation like us. Please note that some of our competitors are now stating this is old news and they have been doing this for years. That is not true and they absolutely DO NOT perform the same work as us. It's funny how they say they do this complex work, yet you never heard of it until now. A good question to ask is, if they spend the time to do this, why didn't they mention this before? It's because they never did it before, and they don't do it now, period. We have seen their units, and we can tell you they do no detail work to the rings of any kind. Polishing doesn't count as detail work, and adding oil to the synchro doesn't work either as the synchro needs friction in order to work efficiently. Adding oil to them will make them feel notchy as they have to work harder to squeeze the oil away.

We believe, and this may sound scary, that most trans builders don't know exactly how a synchro works. It can be pretty complicated and I have talked with several people who have repaired manual transmissions. They give me a 'deer in the headlights' look when I try to go into detail, get their opinion about how a synchro works and how to improve the design. Most trans builders do not have the engineering mentality we have here. We do these improvements as it's terribly important for the synchro to live and operate as intended. We believe this is why our transmissions shift, as some would say, 'like butter' (as in it shifts so smooth it feels like a hot knife through butter). This is a great compliment and we appreciate this very much as it shows the time we spend on your synchros does some good and people notice!

The first thing we check, and we find that we have to modify the most, is the contact between the synchro ring teeth and the slider teeth.

Proper contact of the teeth while the synchro is preloaded by the springs and keys, along with correct contact with the slider, will make a big difference in not only the life of the synchro, but how nice it feels to the driver! Below I made some examples of what we see daily here with BRAND NEW factory OEM synchros if we were to blindly install them untouched.

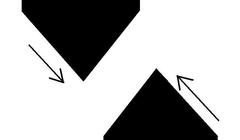

Example below of proper tooth contact if all is perfect in a perfect world. ...or when Jacks Transmissions is done making it right below:

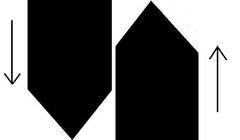

Synchros work by the change in force to the teeth. When the synchro is loaded and trying to synchronize the assembly, the pic above is how the teeth should line up and the arrows show the direction of the force being applied.

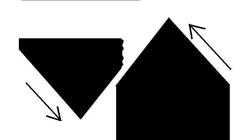

Once the part is synchronized, the force changes and you then get a direct 'UP' and 'DOWN' force to the teeth like the pic below. This will allow the teeth to give way and to 'slip' past each other. When the slider passes the synchro ring, it will then engage (lock) the gear in place. That's how it's supposed to work and look.

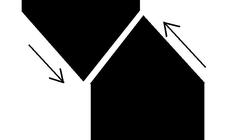

Below I have some examples of what we noticed to be a problem, which is more common than you may think.

The picture below shows how the teeth make contact with most EVOIII, and HD (Heavy Duty) DSM 3-4 synchros, if you were to blindly install them: