The Live Stream below are the benches of owner Jack McGee. He still works on GR6 units from time to time. If you wish to watch your GR6 built in front of your eyes by the owner himself, let us know and we will tell you when 'the man' will be working on it! How many other vendors are comfortable enough to have you watch them work live?? Not prerecorded or edited, but live. We have nothing to hide and what you see is how it's done! Jack is well aware that he will have the most difficulty with his work when people are watching. Let's see him sweat!

Jacks Transmissions prides itself with a shop which is clean and organized. Our service area, for example, has 8 heavy duty parts cabinets to help keep projects together, organized, parts off of the floor and from getting lost. Go to your average shop and look at the projects, and parts for those projects. Are the parts on the floor? Do the workers of the project have problems locating the parts for your vehicle when you visit? Not here. Your parts are kept in a cabinet with a lock and key, and in a safe environment to prevent dirt from reaching them, damage due to sitting on the floor or open bench, and from getting lost.

Our cabinets also have wheels/casters, so when it's time to complete a project, the cabinet can be moved to any of our lifts/bays and sit right in front of the vehicle for easy access.

The pictures below were taken while we were terribly busy and a couple of weeks out on our schedule. Note, even though we are terribly busy, and have many major projects, the shop looks clean and almost empty. That's what we want at all times and are very strict about it.

This is a picture of an EVO X engine project we have below. Note all of this customers parts are in the cabinet and kept clean while the engine is getting rebuilt. No chance of anything damaged, dirty or lost.

Clean work areas also promote efficiency and quality. Your project will be completed faster, cleaner, and will be more reliable than the shop which is a mess. Think about it. If a shop is a mess, what does that say about the work in which they will perform to your vehicle? If the shop is dirty and disorganized how do you think your project will be when completed? We have noticed a pattern with some of our competitors- If the shop is dirty, so is the work. We make sure that doesn't happen here and our work is just as clean, if not more so, than our shop!

Other features of our shop include epoxy flooring, many carts, AC and heat, exhaust recovery system, every exotic tool needed for any project, multiple large tool boxes, and unbelievable cleaning equipment. The more comfortable the environment for the worker, the better the work. If you want the best service, by the best techs, in a very clean shop, you have found it! More pictures below:

Building doesn't look like much on the outside, but inside is a different story and is quite large. Building has 6 offices, large dirty room for unit tear-down and cleaning, clean assembly area, 5000square foot shop service area, large storage room, 2 semi truck trailers docked for storage, and 17,000square foot parking lot. Our equipment, tools, parts, projects and building is always kept very clean and orderly.

Large benches for larger unit servicing, like the GR6 GT-R trans.

GT-R rear sub-frame assembly removed for trans upgrades!

3000GT= Engine rebuild, EVO= T-case rebuild, Sportback= Engine and SST trans rebuild

Jack made the outdoor sign himself.

Electronics station where we can test anything. Jack used to repair consumer electronics when he was a kid and had kept all of his old test equipment which is very useful for testing parts today. Equipment consists of O-Scope, several DC power supplies, variac, signal generator, guiger counter, isolation transformer, Fluke muliti-meter with capacitor tester, assorted bins with any resistor, capacitor, switch, motor, transistor, and diode you would ever need, and a large number of tech manuals including some with specifications about any and all components you would find soldered to a board.

Commonly used parts hung on boards for easy access and better organization.

Our washers run all day every day. More info HERE

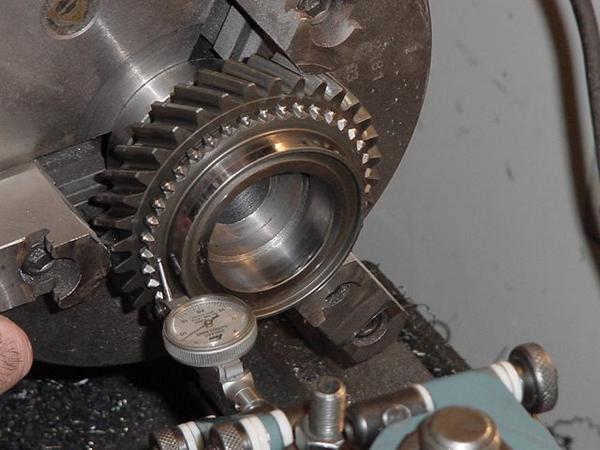

Milling machine

Lathe

Typical busy day at Jacks Trans. Note the huge number of carts. Each cart has 1-2 trans builds worth of work on them. All parts are cleaned and inspected on each cart and ready for the bench. We take the cart over to our work station and perform the build. It looks like a mess, but all has its place and is on-time. When the week is over, everything is put back where it belongs and the shop is clean again for the next week to start all over again.